Machine Projects and Service

An OSRAM Nové Zámky service for business customers

OSRAM offers engineering technology to business customers according to their requests. All that our customers need is an idea. On this basis OSRAM creates a mechanical and electrical design, including detailed process steps and software.

Mechanical parts and electrical components can be produced.

Machines can be assembled and installed at the site of the customer. Also rebuilding and general oveerhaul of machines can be part of the service.

Key benefits of Machine Projects and Services from OSRAM:

- Transforming simple ideas into detailed concepts

- Assembling of machines, installation and support during the run-up phase

- Longterm experience with mechanical, electrical and software engineering

Our main services

Automatic packaging line

Bulb loading – part of the line

Closing brackets – part of the line

Rotary table with products – part of the line

Assembly line for headlight production - proposal in UG

Assembly line for headlight production

Robotics Workstation for the MML1

Robotics Workstation for the MML1

Automatic optical inspection machine – testing and evaluation of parameters from chip

Test module Test machine - testing and evaluation of parameters from chip

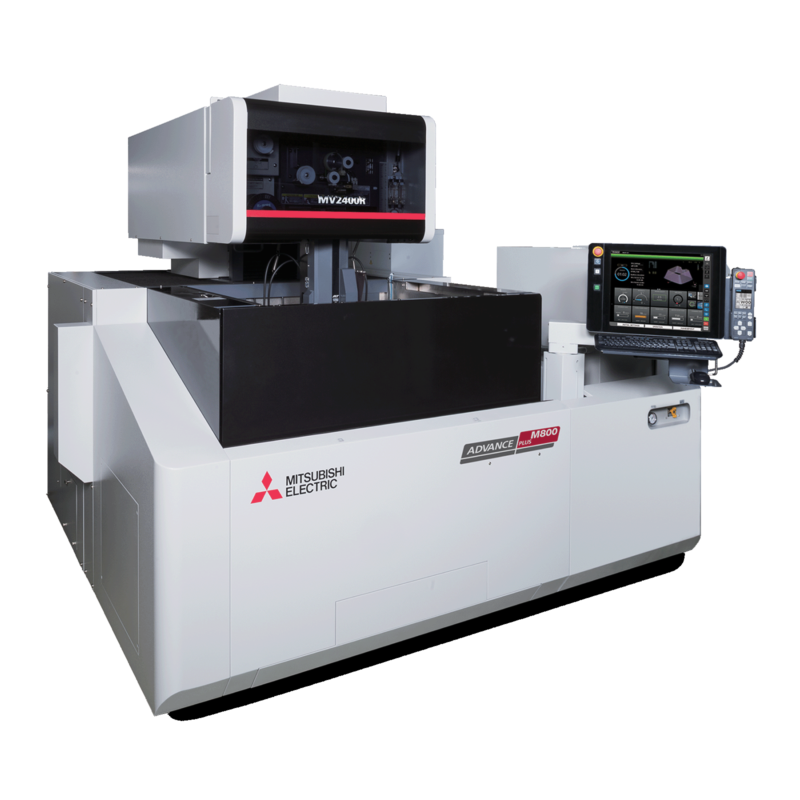

Parts production - example of produced parts from Al, Cu, Fe, stainless steel, plastic

CNC machining center HEDELIUS